| Model | D-2100 |

|---|---|

| Irrigation pump | 3hp vertical multistage pump (Duke pump : DRL8-30), orderer's option is acceptable. |

| Control of nutrient solution |

Venturi injection type (30∼300L/hour) |

| Method of control |

Microprocessor (automatic control depending on the setting by user) |

| Size | (L)100cm x (W)100cm x (H)120cm |

| Weight | 100Kg |

| Power source | 3-phase, 4-wire system, AC380V/60Hz/ 3-phase, 3-wire system, AC220V/60Hz. |

- * Capacity of irrigation pump is subject to change depending on the orderer demand.

- * Product is subject to change without prior notice to improve its quality or capacity.

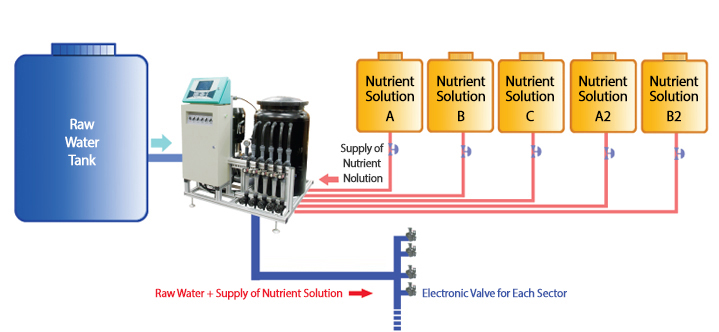

- Diagram for the installation of D-2100 system

- Specification for D-2100 system

Features of D-2100 system

| Sector | Content | Others |

|---|---|---|

| Method of Contro |

•Time control : Irrigation works depending on the setting time to start / finish(3 steps can be controlled) | Each sector can be controlled |

| •Light intensity control : Irrigation works depending on the accumulated light intensity / mix. time / min. time | ||

| •External control : Irrigation works depending on the external signal (moisture sensor, etc) / start time / finish time | ||

| Method of Irrigation |

•Irrigation by flow rate : Irrigation works depending on the setting of 10L unit per sector | Making a choice of the group is possible |

| •Irrigation by time : Irrigation works depending on the setting of time unit, "minute/second," per sector | ||

| Irrigation Sector |

•Irrigation can be extended up to 10 sectors (additional sector is possible as options) | Making a choice of starting valve is possible |

| Choice of nutrient solution |

•Basic nutrient solution : A1 solution + B1 solution + C solution | 3 nutrient solution tanks |

| •Optional nutrient solution : A2 solution + B2 solution C olution (different 2 kinds of crops can be cultivated) |

5 nutrient solution tanks | |

| Feature of two |

•Cultivation of multiple crops by 2 different programs | Setting of 2 groups |

| •Choice of nutrient solution valve per group (A1+B1+C & A2+ B2+C solution) |

1st group : Paprika | |

| •Setting of irrigation/method of control per group | Nutrient solution : A1+B1+C solution | |

| •Choice of electronic valve for starting sector per group | 2nd group : Tomato | |

| •Setting of irrigation cycle(1-9 days) per group | Nutrient solution : A2+B2+C solution | |

| •All settings in 1st group, 2nd group can be duplicated | ||

| •Nutrient solution remained in mixing tank can be removed to work for the next group |

||

| Features of the Program |

•Agitation : Setting(basic) for manual and automatic agitation | |

| •Protection of irrigation pump : Irrigation pump stops when water is low in mixing tank | ||

| •Irrigation setting : Setting of EC/pH/amount of irrigation per sector | ||

| •Irrigation report : Saving weekly amount/number of irrigation/accumulated light | ||

| •Warning of nutrient solution : Setting the limit of high/low value of EC/pH to give warning signal, shutdown. | ||

| •Additional setting of irrigation on specific time, particularly in summer | ||

| •C nutrient solution tank : Choice of setting for acid/alkali | ||

| •Protection of setting value : Locking system for the protection of setting values | ||

| •Output test : Output test for the system can be performed | ||

| •Instruction for use : Instruction for use can be printed out for trial operation | ||

| •1 time irrigation :1 time irrigation works by one-touch button other than time setting | ||

| •Pause : One-touch emergency shutoff function | ||

| •Flow rate calculator : Calculator for the flow rate of irrigation is built in | ||

| •Error display 1 : Indication of non-irrigation sector (when controlling the flow rate) | ||

| •Transmission of handphone text : Operation & defect of the system can be sent by handphone text (option) | ||

| •Transmission of handphone text : Operation & defect of the system can be sent by handphone text (option) | ||

| •Connection to integrated environment control system (option) | ||

| •Connection to the PC for remote control (option) | ||

| •splay of wind direction/wind velocity/EC/pH of nutrient solution (option) | ||

| Features of the Hardware |

•Nutrient solution control valve on the front : Current value of nutrient solution can be controlled | |

| •Installation space can be minimized due to the solution control valve on the front | ||

| •Anti-lightening circuit, components are built in | ||

| •Big size of 6' Korean LCD for a good reading | ||

| •Hydraulic valve : Continuous & safe supply of raw water to mixing tank | ||

| •Relief valve : Maintaining a stable pressure for irrigation per sector | ||

| •U-PVC pipe : Durable & chemical-resistant valves/pipes were used | ||

| •Switch box : Corrosion-resistant stainless steel was used | ||

| •Main structure : Main body is made with 40mm x 40mm aluminum profile |